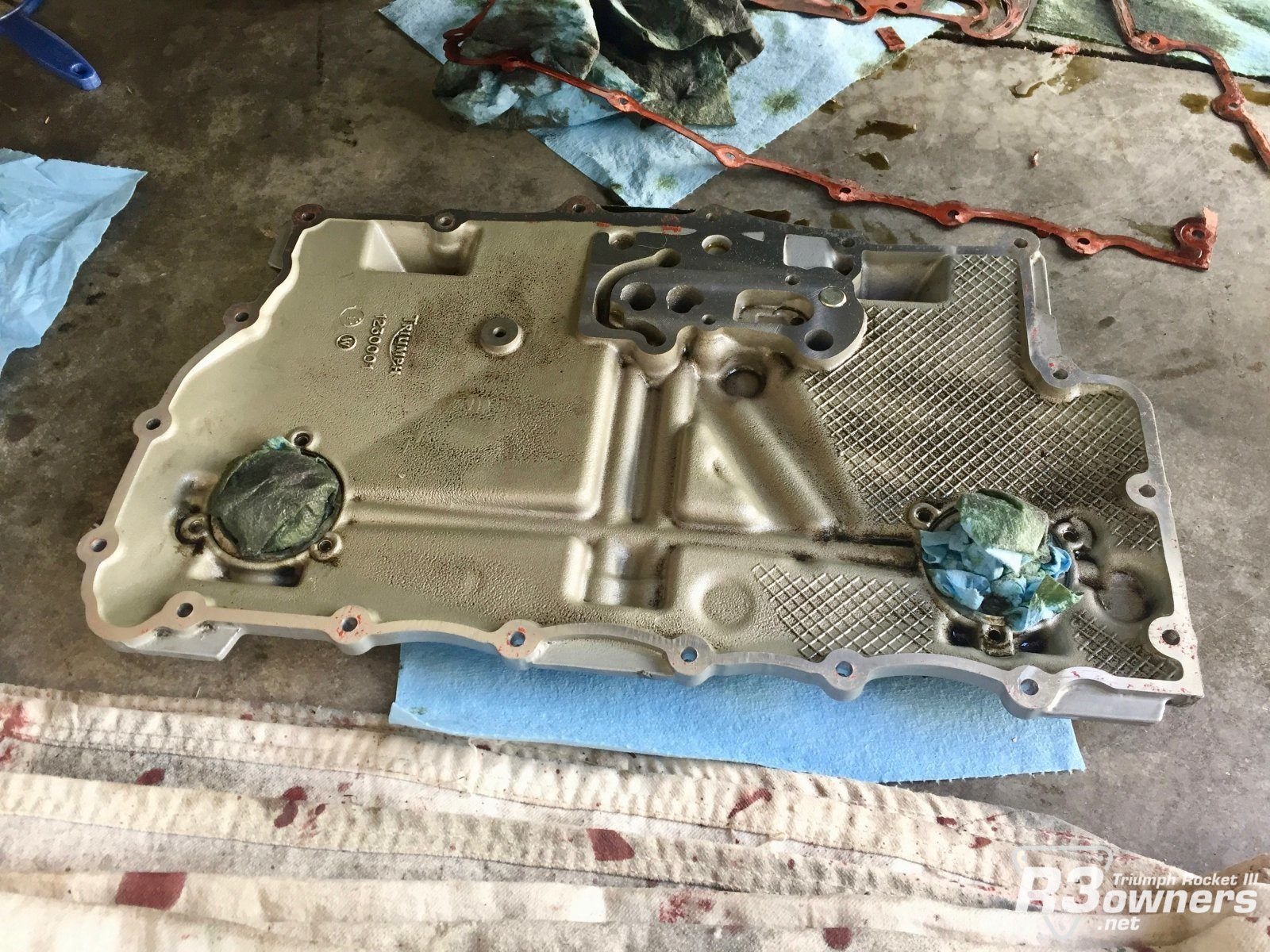

Work in progress. So far so good. Thanks Warp for encouraging me to pull the sump. I'm really glad I did. It's good to clean things out and just learn more about what's in there.

It came down pretty easy and after pouring off some of the extra oil, I wiped out most of the rest along with a bunch of gunk. I'm planning to spray it with brake cleaner to finish cleaning, but come to think of it, I have a steam cleaner I'm always looking for excuses to use, so we'll see. Mostly I just want to be sure the machined surfaces are good and clean for the new gasket.

Am I too concerned about that, or is it important?

I know it's common, but hate seeing these parts in the screens… recognize anything I should be concerned about?

And finally, for good measure, thought I'd share my obsession with organizing hardware and making sure it goes back where it came from. If nothing else it helped me keep track of counting how many bolts I'd already removed and where the remaining ones were.

So that's where it's at! I'm looking forward to getting things finished up this evening. I have a proper (small) oil filter wrench coming tomorrow to remove the old stuck filter. Then hopefully can get it all together and with any luck, get it running tomorrow.