Very good. Thank you! Now that's a response I can believe and also matches what both Scott and ruzzle have said. I will be bringing home a very expensive Fluke pressure calibrator from work and hook that up to the hose on this el cheapo tester I bought (in place of the gauge it came with) to get the real story. Don't know why I didn't think of that in the first place. I suppose there's still a chance the O-ring on the fitting isn't sealing perfectly but my results were consistent with multiple checks. I repeated 3 times - cylinder 1, 2, 3... 1, 2, 3... 1, 2, 3 seating the O ring firmly each time.

However, I've already decided I'm ripping it apart. I did a partial leak down test this afternoon. Did not have the gauge set up to see percent of leakage but simply set the regulator on my air compressor to about 30 psi, removed the check valve from the end of the compression tester hose and blew air into each cylinder with piston at TDC on compression stroke. Took radiator cap off and removed the hose from the crank case vent at my catch can. Visually looked for bubbles in the radiator and listened at throttle bodies, exhaust pipe and crank case vent hose.

Cylinder #1 - Immediately heard air coming out of crank case vent hose and felt it on my arm. It was moving my arm hairs from a few inches away! No indication of air at the other check points.

Cylinder #2 - Very quietly heard air from the crank case vent hose. Could not feel it unless I plugged the hose for a few seconds and then released to let the air escape. No indication of air at the other check points.

Cylinder #3 - The bike immediately started to move forward since it was in gear as rocking it forward was how I turned the engine with a long screwdriver in the hole resting on the piston to see when it stopped rising. Same pressure as the other two cylinders, in gear for each test. No need to even check for leakage after that but I lowered the pressure until the bike didn't move forward. Just a very slight hiss from the vent hose.

So that's enough confirmation for me, it's coming apart. I guess the readings I get with the Fluke calibrator will help me decide if I'll be dealing with 1 piston or 3 and of course what I see visually when I get it apart. This will be the first time I've gone this deep into a motor but with the wealth of knowledge and helpful advice found here on this great forum I feel very confident.

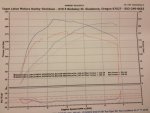

And yes, the previous owner had the bike tuned properly by a knowledgeable tuner but the guy who owned it before him blew a head gasket and replaced it himself. My guess is that's when this damage was done. Maybe it has slowly gotten worse over the last 2k miles it's been ridden. When it was on the dyno they noted that the intake plenum was filling up with oil (listed that way on the receipt he gave me). So the guy I bought it from purchased the catch can but decided to sell it before he installed it. The bike certainly has no lack of power. Can't wait to see what it does with all 3 cylinders at full compression!