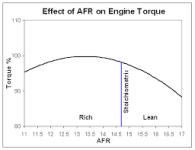

The ECU O2 is a narrow band, it alternates back forth across the set point the ECU is calibrated for, which is somewhere near Stoic, or 1.0 lambda. It has no ability to tune to any AFR other than stoic. That one should be off, on newer ECUs they can trim to target like you want it to do, but this ECU cannot.

My rough in process if you can ride it, is to baby it to a an empty/uphill(hill helps slow the ramp rate of RPM while datalogging, I drag the rear brake at times too to slow it even more) street if possible. While datalogging in 2ndgear to start, as to not put too much load on the engine I climb the street at a set throttle position, holding position as it sweeps up a good bit of RPM, 3500-4000 or so. I coast back down the hill and climb it a few times in various throttle positions, something like 5/10/25.

Stop and do the adjustments in the Powercommander,

roughly 1 number in PC-V table is 1% up to somewhere around 20% +/- fuel.

Repeat as necessary until you have a AFRs consistently between 12.5 and 14.5 through the RPM sweep.

Then I move to 3rd gear and do the same, remember speed creeps up quick

Once 3rd is done to 4500 or so, I start using the freeway when it's not busy and I do all my base cruising area/city riding tuning in 5th gear. It has the highest load and slowest movement out of given cells in the table so you get the best log data. I refine as much of the map as possible at reasonable speeds like this, often doing sweeps from 2000 to 4000 or so.

Once that's done, you can take the fuel map in the PC-V and move it over to TuneECU. I do not use the provided function in TuneECU, I've not had good luck with it. I manually move then PC-V trims into the TuneECU map +1% e.g. +12% in in PC-V I would put +13% in the TuneECU map area that corresponds. Interpolate areas as required. Then zero out the PC-V trim table.

From there I just datalog while I'm out riding and correct when I get home directly in TuneECU, leaving a zero map in PC-V.

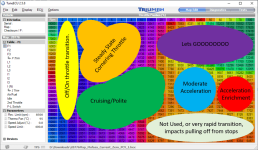

When you're satisfied with that part of the table comes the hard/risky part... larger openings. I look at the general shape of the map I've build using the curve visualizer in TuneECU like this:

Then I shape the curve so that each RPM row, provides a similar shape but with higher values as RPMs climb. The exceptions are understanding where peak torque is, there will be a non-linear increase as you cross peak torque where it wants more fuel, then it will slowly taper the rate of increase from peak torque to peak horsepower, but each subsequent row will still still use more fuel than the last. Say my peak torque is at 5200, from 4400 to 4800 I may add 5%, then from 4800 to 5200 8%, then from 5200 to 5600 back to 6%, the rate of gain slows.

There's also an inflection point, at least on my setup, for me it's at 15%. From 15% to 20% there's a very non-linear increase in airflow, thus, the big jump in fueling. Your inflection point will be higher than 15%, it's because of my bored throttlebodies. As I remember, stock, it's around 25%, you can see it in the stock maps too.

I lean towards too rich vs too lean.

After that is done I go datalog some progressively increasing throttle 3rd gear pulls 40/50/60 etc, backing out of it the moment I see 15:1 on the gauge. or feel anything odd. Check logs, adjust, repeat. This part takes a long time, and its loud, and its fast, and its illegal AF- be cautious. When 3rd is tuned reasonably well I do some 4th and 5th, but ... there's no safe way to do high RPM 4th/5th on the street so I don't do it a lot.

This point is when I call the shop and schedule a dyno. I've routinely been about 10% down on power vs the fully dyno tune, but the dyno tune feels 100x better, and its because of something else you asked: Acceleration Enrichment. Will post in separate section.