Ignore the "Located Camshafts" Image in the manual section 3.12, it's as wrong as wrong gets.

Step 1: Order 16 of these and put away the stupid T30 tool, grab your 10mm instead.

BF6X40FCLZ - Flange Bolt 10.9 Zinc [BF6X40FCLZ] - $0.44 : Bel-Metric, Metric Hardware, Metric Fasteners, Metric Bolts, Metric Nuts & Time-Sert Thread Repair

- Check all valve clearances, source shims required as needed.

- Turn to TDC, remove tensioner, release all ladder bolts in correct order. Remove chain, ladder and cams and replace shims required.

- While at TDC set the Intake cam in so the #1 lobes are pointing towards the throttle bodies. Set the Exhaust cam so the #1 lobes are pointing towards the exhaust, this is the most relaxed position and does NOT risk valve to piston contact unless you turn the motor over before aligning the cams. As below but your ladder won't yet be in place:

- Lube all lobes and journals.

- Set the cam chain in place on all gears.

- Set the cam ladder on, lube all bolts with oil and finger tighten all bolts.

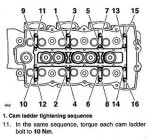

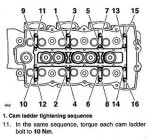

- Tighten all ladder bolts in 3 or 4 even steps, ending with a final torque @ 10nm.

- Check alignment of the cam gear marks as seen in the manual. You can use 2 x 20mm wrenches instead of the tool they specify. Just lift the chain off 1 cam, use the 20mm to turn it to the right position and lower the chain. Using your assistant have them do the same on the other cam, or, if you can manage holding the first in place while adjusting the second so the marks are lined up, you're golden. Leave all slack on the tensioner side of the chain the best you can.

- Install the tensioner.

- Turn engine 4+ times clockwise. Stop at TDC with the cams situated as earlier, intake #1 pointing to throttle boddies, exhaust #1 pointing at headers.

- Check alignment marks again.

- Double check all valve clearances if shims were replaced.

- Refit cam cover using RTV/anerobic sealant on the semi-circular sections, torque to 10nm.

On first start hold at 1,500 RPM for 2 minutes, then let idle until fan turns on.

Dun

If you go through it and the exhaust cam keeps ending up 1 tooth off, so it's pointing too low instead of at the intake cam mark when you align them, leave it 1 tooth pointing too high before installing the tensioner and the tension will pull it in place.