Bedifferent

Old man on a bike

You are probably sick of the shim tool, but I thought I would post one more version I made.

I fabricated one of the posted tools for Paul, but he expressed some concerns with the tool ideas. He was concerned about having only one of the screws in place on what he described as a somewhat fragile ladder. When turning the cams to depress the valves he thought it might put undue stress on the one and only bolt holding things in place before installing the tool and tightening it down to hold the bucket down. Correct me if this is wrong @Joesmoe

To solve the problem, I revamped the posted plans and made the fingers longer to compensate for the height of adding a M6 bolt and flange nut first before turning the cams to depress the valves. I also put a small bend in the fingers to position the two bucket fingers in the same spot on the bucket where the posted straight leg tool would have landed.

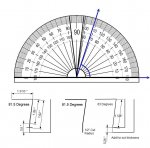

I used a 2" wide concrete mounting bracket from Menards (as shown) and laid it out as to how it had to be cut. Hacksaw time! I drilled multiple small holes at the inside of the bracket bend and was able to snap the the center finger cut out. There was some work with a file to smooth things out.

I found some M6 X 60mm set screws (Amazon) to be put in to replace the removed ladder bolt... you then could tighten things down with a flange nut before bolting the shim tool down on top of the other flange nut. The feet have 1" curves ground on the tips to better match the lip of the bucket. The edges are sharp and crisp. The shim tool as a whole can be shortened, holes elongated, washers added for spacers, fingers bent...whatever... for a perfect fit... I hope.

Since the idea has not been tested by anyone yet, it remains to be seen if it will work. Based on other posted plans, I see know reason why it shouldn't. Lots of room for personal tweaking when the time comes. Pictures