Gregger

Living Legend

I agree with your comments. I guess it depends on the type of groove cut in the shaft. If the groove in the shaft is cut with minimal radius on the inside edge opposite the gear, that diagram would be wrong and the circlip installation backwards. If the groove is cut with a pronounced radius on the inside edge (usually to prevent cracking of the shaft) it would work and you would want the beveled circlip edge against it. I would go with what Triumph recommends in their manual since it appears to be opposite to that Wikipedia diagram posted below.That diagram makes no sense to me. A shallow cut groove like our transmission would surely pop the circlip out with a little force and circlip flexing.

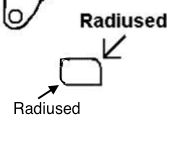

Notice the radiused top of snap ring matches radius of work piece. If there is no radius on work piece, I would flip the snap ring. I don't think the Triumph tranny shaft circlip grooves are heavily radiused.

=

=