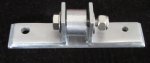

I think I mentioned that I would post pictures of what I came up with for installing the set of P1AA horns on my R3T so that it may help someone else thinking of doing this. Or it may give someone and idea for a similar setup. The bracket is made up of 2" x 2" aluminum angle 1/8" thick (cut down to fit the bracket) and 1" aluminum strap 1/8" thick and 7/8" round bar aluminum drilled as shown. I brazed the aluminum angle and flat stock so it's all one piece because it only took a couple minutes but that really isn't necessary. The hardware is stainless steel. Nothing is permanently altered on the bike and it can be put back to factory stock in a couple minutes if, for some reason, someone actually wanted the puny horn that came with the bike. The bolt and SS nyloc nut are not tightened down in the pictures so things aren't pulled into alignment perfectly. This setup gives a lot of adjustment for swinging the horns into the best place. The openings should be pointed down or nearly down, of course. The picture of the horns and bracket held in my hands is roughly how it will be oriented when installed but I'll swing the horns to the best position before tightening them down.

I did get a relay and harness even though these horns don't need it and others who installed them have reported that they work fine without a relay. I just figured, why not use a relay? Here's where I got the relay harness. Of course, it would be easy to make one up but I figured I'd get lazy.

Stebel HF80 Wiring Harness

Here's how it's mounted: When you remove the original horn, there's a spacer block you will remove and won't use for the new horns. The hole the horn was bolted to is one of the holes that the new bracket will mount to. If you look to the left of that hole when facing the front of the bike, you'll see a smaller bolt in line with the one the horn was mounted to. These are the holes the new bracket will bolt to. The long (larger) bolt that bolted the orignal horn and spacer down will be too long so you will have to get a shorter one or cut down the original. I wanted to save the original bolt in case someone in the future wants to put things back to stock so I bought a new SS bolt. It's a little long so I'll have to cut it down. The smaller bolt to the left should work but I bought a new one that is longer and I'll cut it down so it's about 1/4" longer than the original bolt to make up for the thickness of the new bracket.

Of course, I checked everything all along so I know that there's ample clearance and the horns won't hit the fender when the forks are compressed.

Edit: I've added a couple pictures of the horns installed on the bike. It may look like the horns are closer to the fender than the actually are because the horns are farther back than the top of the fender. It's a slight optical illusion. There's more space between the horns and the travel in the forks before the outer (top) tube of the forks bottom out on the inner (bottom) fork tubes. Tomorrow I'll wire up the relay harness.